Marking of fasteners

Robot-assisted, fully automated laser marking for fasteners

Discover the impressive technology of robot-assisted and fully automated laser marking for marking special screws and fasteners in our latest video.

With this advanced method, we offer a variety of advantages:

1. high quality: even with the smallest marking, the quality remains high, making it ideal for the highest decorative requirements.

2. high repeatability: every marking is precise and consistent for uniform product labeling.

3. gentle on the material: the non-contact process leaves the material undamaged.

4. abrasion and chemical resistant: Our labeling is durable and resists both abrasion and chemical influences.

5. traceability: With the ability to create barcodes, QR codes and data matrix codes, we offer an ideal solution for tracking components.

6. counterfeit-proof: Our laser marking contributes to the security of your products and protects against counterfeiting.

7. suitable for almost all materials: Regardless of the material of your components, our laser marking is an effective marking method.

Whether screws, turned parts, drawing parts, milled parts or other connecting elements - our laser marking offers an efficient and high-quality solution for marking your products.

When you view and play embedded videos on www.gueldner.com, the provider (YouTube) may be able to store your access and analyze your behavior. If you activate the content, i.e. agree to view and play it, a cookie is placed on your computer to record that you have agreed to this in your browser. This cookie does not store any personal data.

For more information, please see our privacy policy and cookie page.

You can also use this link to access the video directly on the plattform of the provider: https://youtu.be/xxLjfTm4IZs

Hexagon head screws

The marking of hexagon head bolts with manufacturer's mark and strength classes is mandatory for all strength classes and a nominal thread diameter of d ≥ 5 mm.

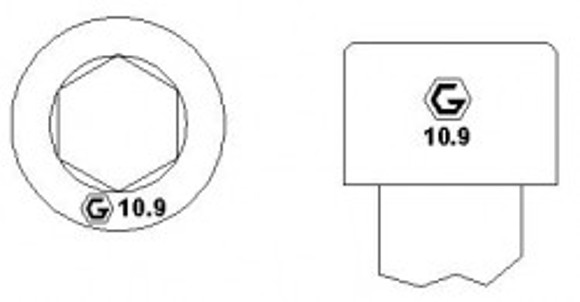

Socket head screws

The marking of hexagon socket head cap screws with manufacturer's mark and strength classes is mandatory for strength classes ≥ 8.8 and a thread diameter of d ≥ 5 mm. The marking of the screw is to be applied where the shape of the screw allows it.

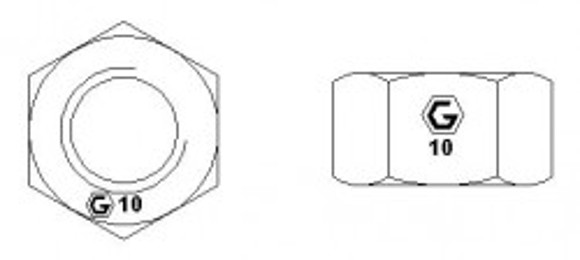

Hexagon nuts

The marking of hexagon nuts with manufacturer's mark and strength classes is mandatory for all strength classes and with a thread of ≥ M5. The hexagon nuts must be marked recessed on the bearing surface or a wrench flat or raised on the chamfer. Raised markings shall not extend beyond the bearing surface of the nut. As an alternative to marking by means of the strength class code, marking can also be carried out using the clockwise system (see also DIN EN ISO 898 Part 2).

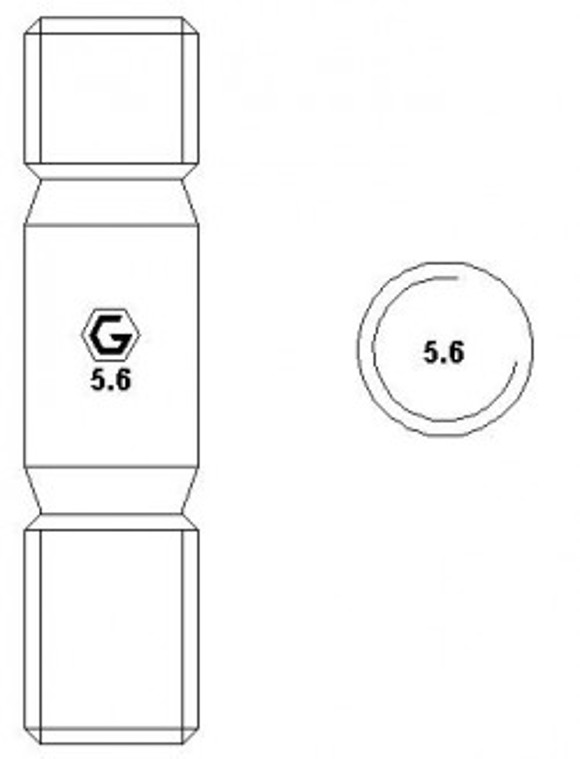

Studs

Stud bolts shall be marked with the manufacturer's mark and with the mark of the strength class or the alternative mark. The marking is mandatory for stud bolts of property classes 5.6 to 12.9 with a nominal thread diameter d ≥ 5 mm. The marking shall be applied to the thread-free part of the stud bolt. If marking is not possible there, marking with the strength class shall be applied to the short threaded end (nut end). The manufacturer's mark may then be omitted. The last procedure applies in particular to stud bolts with a tight-fit thread.

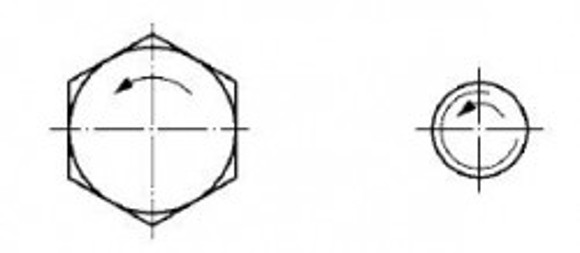

Hexagon bolt and nut with left-hand thread

Bolts with left-hand thread and nominal thread diameter d ≥ 5 mm must be marked with an arrow indicating the direction of rotation either on the surface of the head or on the crest of the thread end. Hexagon bolts or nuts with left-hand thread may optionally also be marked with a circumferential notch.

Material code

Often, for reasons of space, the finished parts are marked with a material abbreviation:

| Kurzzeichen | Werkstoffnummer | Kurzname |

|---|---|---|

| KB | 1.5680 | X12Ni5 |

| Y* | 1.1181 | C35E |

| YK | 1.1181 | C35E |

| YB | 1.5511 | 35B2 |

| KG | 1.7218 | 25CrMo4 |

| KA | 1.7219 | 26CrMo4 |

| G | 1.7258 | 24CrMo5 |

| GA | 1.7709 | 21CrMoV5-7 |

| GB | 1.7711 | 40CrMoV4-6 |

| GC | 1.7225 | 42CrMo4 |

| V* | 1.4923 | X22CrMoV12-1 |

| VH* | 1.4923 | X22CrMoV12-1 |

| VW | 1.4913 | X19CrMoNbVN11-1 |

| S | 1.4986 | X7CrNiMoBNb16-16 |

| SD | 1.4980 | X6NiCrTiMoVB25-15-2 |

| SB | 2.4952 | NiCr20TiAl |

Y* V* VH* |

Only for nuts For 1.4923 with Rp0,2 ³ 600 N/mm² For 1.4923 with Rp0,2 ³ 700 N/mm² |

|

Sources: DIN EN ISO 898-1 - Mechanical properties of carbon and alloy steel fasteners - Part 1: Screws with specified strength classes - Standard and fine pitch threads DIN EN ISO 898-2 - Mechanical properties of carbon and alloy steel fasteners - Part 2: Nuts with specified test loads - Standard threads DIN EN 3506-1 - Mechanical properties of stainless steel fasteners - Part 1: Screws DIN EN 3506-2 - Mechanical properties of stainless steel fasteners - Part 2: Nuts DIN 267-13 - Mechanical fasteners - Technical delivery conditions - Part 13: Parts for bolted joints with special mechanical properties for use at temperatures from -200 °C to +700 °C |

||

Sonderschrauben Güldner GmbH & Co. KG collects and processes the personal data entered in the form in order to process the requested inquiry for you. Please note the marking of the mandatory fields on the forms. The legal basis for this processing of mandatory data is Art. 6 para. 1 lit. b GDPR, implementation of a pre-contractual measure. The processing of the data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f GDPR. This permits processing that is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve the quality of our advice and to be able to contact you more easily in the event of any queries. The data collected will only be stored by us for as long as is necessary to process your request and to contact you. It will then be deleted. Translated with DeepL.com (free version)

Additional data protection information, in particular on your rights to information, rectification, erasure, restriction of processing, objection and complaint, can be found in our privacy policy.