Headless bolts

Welcome to Sonderschrauben Güldner, your reliable partner for high-quality fasteners. Our headless bolts such as stud bolts, threaded rods, threaded pins, grub screws and screw bolts are specially developed to meet the demanding requirements of industry, such as mechanical engineering, apparatus engineering and the automotive industry. Through precise manufacturing and the use of first-class materials, we offer you solutions that are convincing in both standard and customized designs.

Stud bolts are ideal for applications where frequent loosening and fastening is required. They are characterized by the absence of a forged head and have a thread at both ends. The continuous shank between the threads has the same diameter as the thread. With these screws, a distinction is made between the nut end, which is intended for the fastening nut, and the screw-in end, which is screwed into the corresponding component.

A major difference between DIN threads and screws with heads lies in the determination of the nominal length. While the total length up to the flat surface is specified for threaded parts according to DIN and cap screws, the nominal length for stud bolts refers to the area without phase (from the first load-bearing thread).

Differences between stud bolts, stud screws, threaded pins and other headless bolts

The terms stud bolts, stud screws, grub screws, threaded bolts, studs, threaded rods, stay bolts and screw bolts are often used interchangeably, but there are some differences and specific use cases that are worth highlighting.

In terms of threads, studs and stud bolts often have an unthreaded shank in the center, while stud bolts can also have an unthreaded shank and can be fully threaded. Grub screws are fully threaded and have no heads. Threaded studs, on the other hand, can be fully threaded or have an unthreaded shank in the center.

Stud bolts and grub screws are often manufactured to DIN standards, while stud bolts and studs often conform to international standards such as ASTM or ASME. Depending on the application and region, threaded studs can conform to different standards.

Stud bolts are versatile and are widely used in various industries. Stud bolts are preferred for flange connections especially in the petrochemical and piping industries where high pressure and temperature requirements must be met. Grub screws are ideal for applications where a smooth surface is required. Threaded studs are versatile and can be used in various industries.

Stud bolts are fastening elements that are used in industry to connect heavy components. They are longer than grub screws and have a thread at both ends. One end is screwed into a component, while the other end is intended for fastening a nut.

Unlike grub screws, which are used for fine adjustments in smaller applications, studs and stud bolts are known for their high load capacity and their use in critical connections. They follow strict industry standards, such as ASME B16.5, and are available in various sizes and materials to meet the specific requirements of projects such as flange connections in the chemical and petrochemical industries.

While grub screws are often used in concealed applications, stud bolts are visible and central elements in the construction of machinery and equipment. Their robust design makes it possible to ensure a secure and durable connection even under extreme conditions.

Stud boltsShape:

Stud bolts have a threadless shank in the middle and threads at both ends.

Standards:

In Germany and Europe, Studs are often manufactured according to DIN standards such as DIN 835, DIN 938 and DIN 939.

Stud bolts are manufactured according to international standards such as ASTM, ASME or other specific industry standards.

Application:

Studs are used particularly in mechanical engineering, apparatus engineering and the automotive industry to securely fix and secure components. They are ideal when a tight fit and high load-bearing capacity are required.

Stud bolts are often used in the petrochemical industry, in pipeline construction and for flange connections. They offer high tensile strength and are ideal for applications where high pressures and temperatures prevail.

Materials:

Studs can be made from various materials such as steel, stainless steel, special materials and other special alloys.

Typically, stud bolts are made from high-strength steel, alloy steel and corrosion-resistant materials.

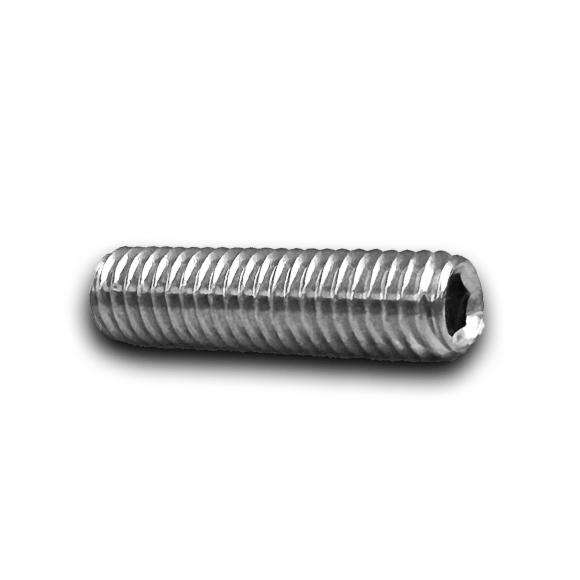

Grub screws are special fastening elements without a head that are screwed into components through an internal thread. They differ from stud screws and stud bolts, which are designed for structural connections in larger machines and systems. Grub screws, on the other hand, are used for the precise positioning and fixing of components.

Equipped with a continuous thread, they enable fine adjustment and are tightened using an Allen key or a Torx screwdriver. Depending on requirements, the ends of the grub screws can be conical, spherical or have an annular cutting edge to ensure optimum force transmission.

These small but essential components are indispensable for precision mechanics, where precise adjustments and permanent fixings are essential.

Grub screwsShape:

Grub screws are fully threaded and have no head.

Standards:

Grub screws are often manufactured according to DIN standards, such as DIN 913, DIN 914, DIN 915, etc.

Application:

Grub screws are often used to fix parts in machines and devices, especially where a smooth surface is required.

Materials:

Grub screws can be made from various materials such as steel, stainless steel, brass and others.

Bolts are true all-rounders in fastening technology. They are equipped with a partial thread that enables them to create both fixed and adjustable connections. This flexibility makes threaded studs particularly valuable for constructions that require quick assembly and disassembly, such as in trade fair and stage construction or modular systems.

Threaded bolts, also known as threaded studs, have a continuous thread and can be fastened with nuts at both ends. They are ideal for applications that require high tensile strength and can therefore be found in many areas of industry.

Threaded studs, on the other hand, are the preferred choice for dynamic applications where flexibility and adaptability are required. They are easy to install and remove, making them an indispensable tool for many engineers and technicians.

Threaded studs and boltsShape:

Threaded studs and threaded bolts have a cylindrical body with a partial or continuous thread.

Standards:

The standards DIN 976-1, DIN 976, DIN 1433/1443 and EN 22340 are often used for threaded bolts and studs.

Application:

Threaded studs and threaded bolts are used in a variety of applications where a reliable and strong connection is required.

Materials:

Threaded bolts and studs are manufactured from various materials.

Stay bolts, also known as stud bolts, studs or pins, are essential fastening elements in industry. They provide strong anchoring for a variety of applications and are characterized by their durability and precision. Our stay bolts meet the highest quality standards and are available in various sizes and materials to meet your specific needs.

Stay boltsShape:

Stay bolts are characterized by their cylindrical shape, which enables an even distribution of force.

Standards:

Stay bolts are subject to certain standards that define their dimensions, properties and areas of application. The relevant standards for stud bolts include DIN983, DIN 939 and DIN 835.

Application:

Stay bolts are known for their universal applicability in a wide range of industrial sectors, where they ensure a reliable and durable connection.

Materials:

Stay bolts are manufactured from steel, stainless steel and other materials depending on the application to ensure maximum strength and corrosion resistance in all areas of use.